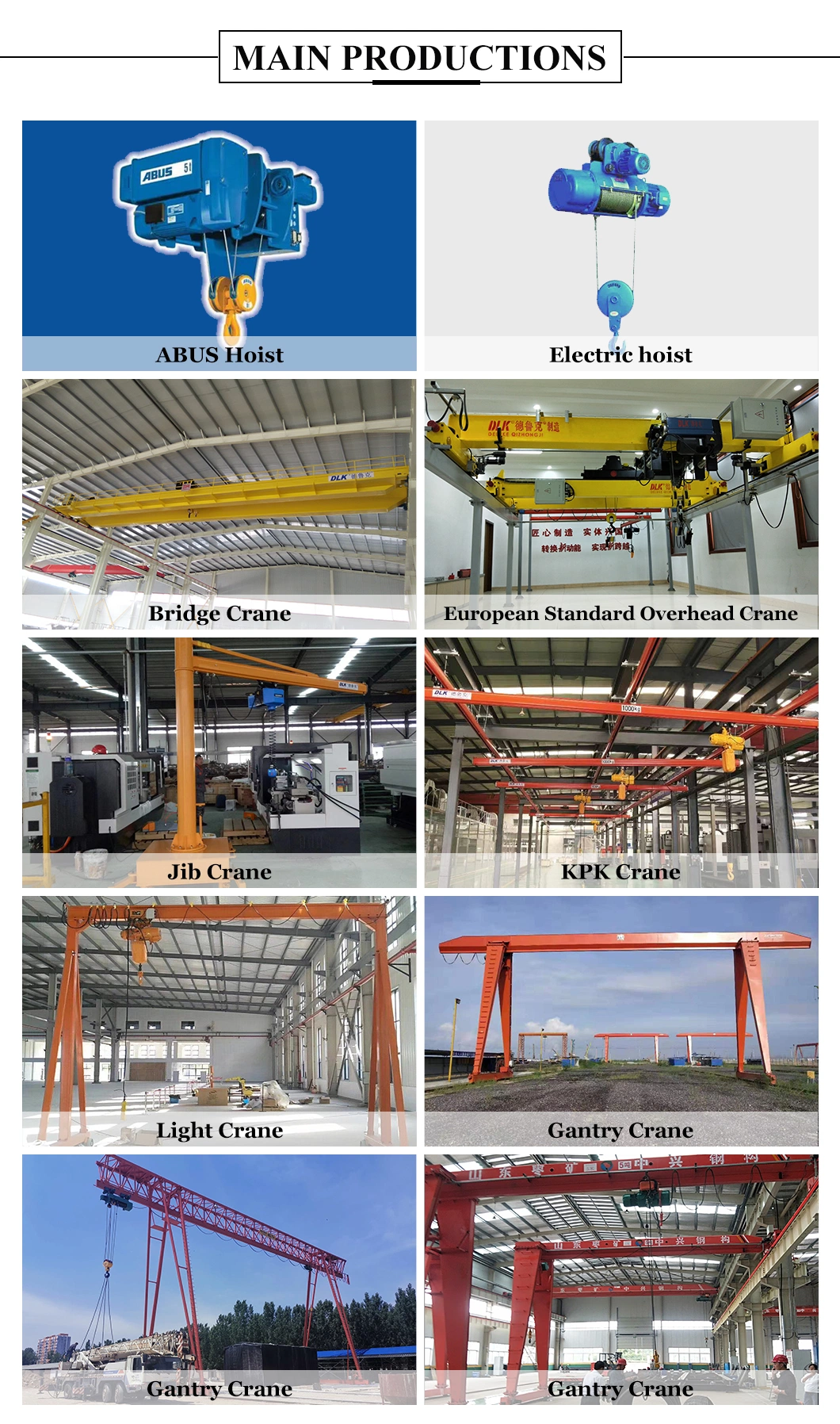

Light Duty Dlk Kpk Suspend Rail Flexible Crane System

Basic Info.

| Model NO. | kpk 0.25-2t |

| Maximum Lifting Weight | <20t |

| Main Girder Form | Single Girder |

| Type | Beam |

| Hoist Speed | 2-8m/Min |

| Capacity | 0.25t 1t 1.5t 2t |

| Lifting Speed | Variable Speed (Standard) |

| Production Name | Kpk Flexible Cranes |

| Span | Customize |

| Keyword | Kpk Flexible Cranes |

| Transport Package | Export Packing |

| Specification | Customized Size |

| Trademark | DLK |

| Origin | China |

| HS Code | 8426192900 |

| Production Capacity | 10000 Per Year |

Product Description

Product ParametersPRODUCT FEATURES

★Good reliability, high stability KPK light crane components of the system are all standard modules, you can ensurehigh-volume, high-quality production,★System module is the mainstay of three sizes of rolled profiles, intensity good rigidity,light weight, to ensure stability of the system.★KPK system adaptable plant each station according to the needs, flexible design and installation of the crane system,from sentinel transported to a high accuracy multi-point,★Multi-beat automated conveyor line, can be arbitrary combination. The plant can be used for new designs can also beused to modify or extend the old system.★It is easy to install, cost-effective KPK system installation is very convenient, and the standard profiles bolted between the modules can only be used to save the factory space and area,★Reducing the human resources greatly, improve production efficiency, thereby reduce energy consumption, improveenterprise efficiency.★System can be operated manually or can achieve automatic and semi-automatic operation, efficient operation.

Three advantages of the product:

1.European modular designSpecial light weight, the friction between the pulley and the track is small, easy operation, can be very quickly transported handling those inconveniently heavy workpieces, to adapt to plant station requirements. 2. Flexible suspension means can swing rail cranesIt can effectively absorb the braking effect caused when horizontal impact load can be easily mounted on the light inside the steel plant. 3. Multi-track suspensionCover a larger warehouse and production area, the crane can easily be moved by hand.Note: Crane span greater than 6m, crane loads over 200kg, in order to reduce operator work load and recommended electrically driven walkingprogram.

| Product Name | KPK flexible beam crane |

| Model | KPK 0.25-2T |

| Span | 3-9M |

| Lifting height | 6M |

| Hoisting speed | 2-8m/min |

| Trolley speed | Manual or Motorized |

| Gantry speed | Manual or Motorized |

| Working temperature | -25°- 40° |

| Working level | A3-A5 |

| Control model | Pendent Control, Remote Control, Crane Cabin |

| Brand | DLK |

| Capacity of kpk crane system | 250kg, 500kg, 1000kg, 1250kg, 1600kg, 2000kg, |

| OEM/ODM | Available |

Q1. Can the cranes be customized?

Yes, every customer's working condition is different, all of our products can be customized depend on customers' requirements. Please give us the information as clear as you can, so we can give our best design to suit for your demands.

Q2. How many operation methods for my selections?

We provide pendent controller with push button control type, remote control type or cabin control type. Please tell us what kind of operation way you need.

Q3. I have low headroom in my workshop, is it possible to install a crane in it?

We have special products for low headroom workshop, our engineer can give the best design according to your dimensions.

Q4. Do you supply lift tools?

Yes, we can provide any kind of lifting tools such as hook, electromagnetic, grab bucket etc...

Q5: In order to offer the most suitable design solution for you, it will be great helpful if you can offer us the following information to us:

1. Lifting capacity.

2. Span length. (rail center to rail center)

3. Lifting height. (hook center to ground)

4. Have you installed the rails? Do you need us to supply the rails? How long is it? 5. Power supply: Voltage.

5. Working condition: What kind of material to lift? Temperature?

6. It would be much better if it is possible for you to offer the drawing photo of your workshop.