Category

Customized Heavy Equipment Undercarriage Parts Crawler Crane Track Pad Track Shoe Construction Machinery Parts

Wear-resistant Steel Heavy Crane Crawler Share Parts Description OEM/ODM Request Is Very Welcome! Production Process We

Basic Info.

| Model NO. | Crawler Crane Track Shoe |

| Origin | China |

| Production Capacity | 300 Tons Per Month |

Product Description

Wear-resistant Steel Heavy Crane Crawler Share Parts

Description

| Product name | Crawler Crane Track shoes Crawler Crane Track links Crawler Crane Track pads |

| OEM | Acceptable |

| Materials | Alloy steel Casting,wear-resistant steel |

| Resin sand casting | ≤10Ton |

| Manufacturing Process | Water glass sand casting, Resin sand casting |

| Heat Treatment | Quenching Tempering |

| Hardness | HRC52-60 |

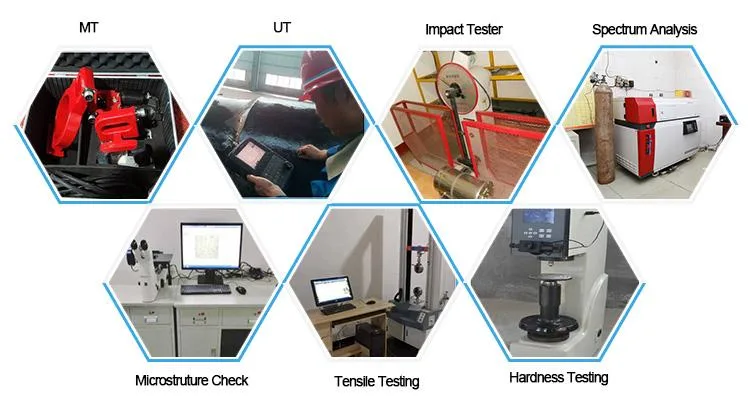

| Test item and method | Chemical composition: Spectrum Analysis; Hardness:HB\HRC\HV Hardness tester Metallography detection: Microscope Internal defects: Ultrasonic flaw detector Surface defect inspection: Magnetic particle detector |

| Application | Heavy equipment, crawler crane, Excavators, Bulldozers |

| Surface treatment | Shot-blasted and Painting |

| Package | Plywood Pallet |

| Payment Term | T/T, L/C |

Production Process

We have water glass sand casting process and Resin sand casting process, we'll choose the most suitable process according to product requests. Meanwhile we have 20T-LF refining furnace and 5T medium frequency furnace that can produce cast steel material products with different national standards, such as: ASTM, EN, DIN, BS and GB.

According to products requests, we will use different heat treatment processes, like Normalizing, Quenching, Tempering, Annealing, Carburizing, Nitriding and Induction hardening.

We also have large machining equipment that can satisfy the needs for most of our customers, such as: Φ200 CNC floor type boring machine, Φ130 CNC floor type boring machine, 8m planomiller and 4m Vertical lathe, etc. Inspection

SYI regards quality as the essential part of our business success. Based on your requirements, we have raw material in-coming inspection, process control and pre-shipment inspection. With advanced test equipments such as spectrometer, CMM, tensile strength tester, microstructure, hardness tester and Impact tester etc, SYI is able to apply sufficient chemical and physical inspection. According to your request, we are also capable to do X-Ray, Magnetic Testing, Ultrasonic Testing and liquid Penetrant Examination.

ApplicationCompanyAbout UsSYI provides OEM Casting & Forging services based on your drawings , samples , or just an idea ! After technical analysis and individual QCP for each project , the most suitable manufacture process will be recommended.SYI starts our business since 1990 ' s of machined and un-machined in a variety of industry . We have over 100,000 products till now with the support of a specialized team including 50 engineers , inspectors and customer services .Cooperative Brand