Category

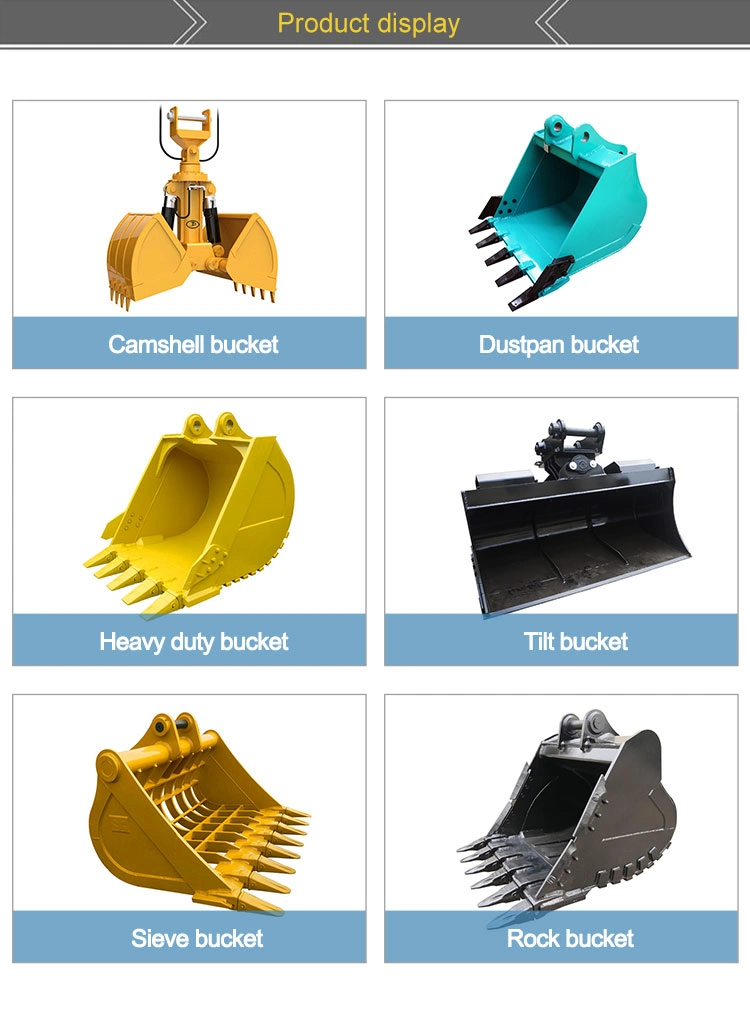

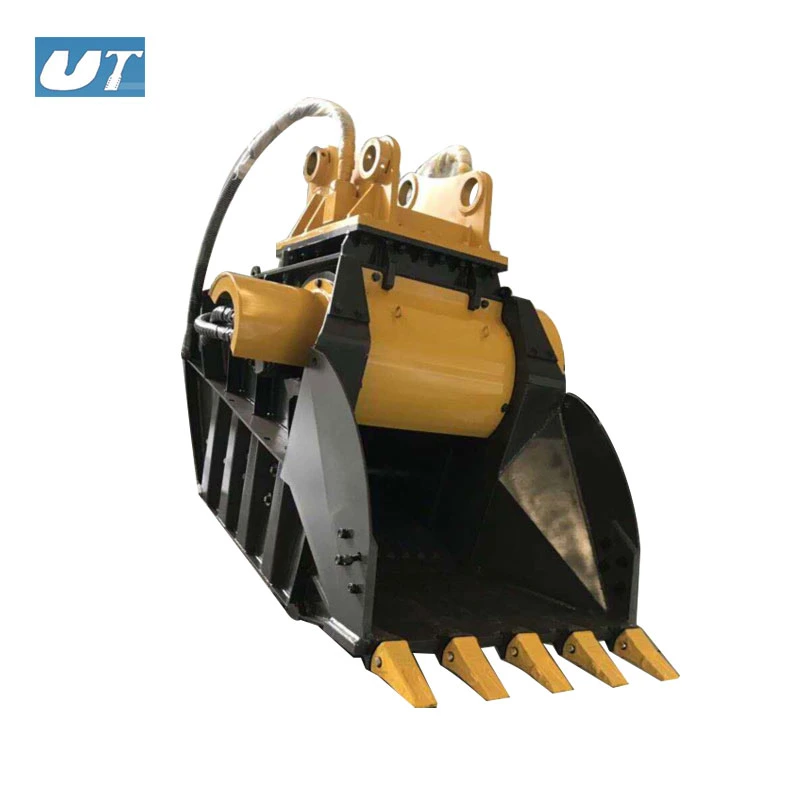

Wholesale Excavator Bucket Excavator Clamshell Bucket Excavator Clamshell Grab Shell Bucket

Main Features Superior Performance 1. Quenched&Tempered Alloy Steel 140,000-150,000 psi MIN. Yield, 320-400 BHN is used

Basic Info.

| Transport Package | Export Package |

| Trademark | UT |

| Origin | Shandong China |

| Production Capacity | 1500 Sets/ Month |

Product Description

| Buckets' Strength---We Made Things Tough! | |||

| Type | Material | Specifications | Suitable Brand |

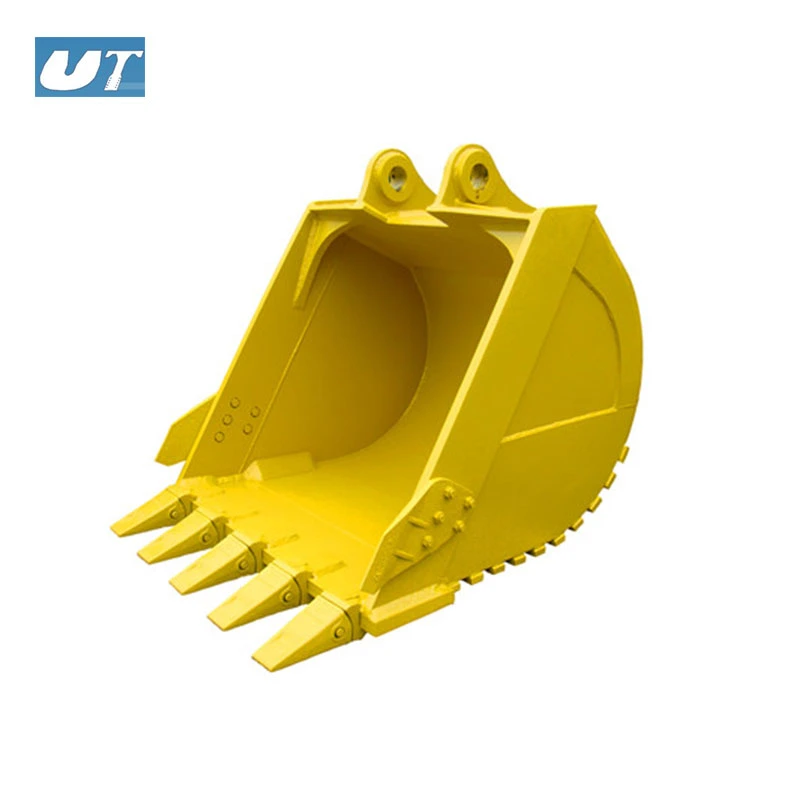

| General Purpose (GP) Bucket | Q355 | 1. All steels importing from CSG(TOP 500 in China) ensuring great quality 2. OEM are available | KOMASTU, CAT, HITACHI, VOLVO, SUMITOMO, SANY, JCM, SHANTUI, ZOOMLION, XCMG, LONKING, SDLG, LIUGONGKOBELCO, DOOSAN, CASE, KATO, HYUNDAI, JCB, LIEBHERR, KUBOTA, YANMAR, TAKEUCHI, IHISCE, ETC. |

| Heavy Duty (HD) Bucket | Q355+NM360 | 1. Quenched&Tempered Alloy Steel 140,000-150,000 psi MIN. YIELD 320-400 BHN is used in cutting edge lower sidecutter sections, wear strips&side wear plates 2. High strength wear strip configuration, affords the best possible protection to the bottom of the bucket | |

| Severe Duty Bucket | Q355+Hardox-500/NM360 | 1. Lower sidecutter sections are drilled & countersunk to accept sidecutters or other options | |

Main Features

Superior Performance1. Quenched&Tempered Alloy Steel 140,000-150,000 psi MIN. Yield, 320-400 BHN is used in cutting edge, lower side cutter sections, wear strips & side wear plates.2. Optimized profile for better filling & dumping Enhanced Durability 1. Strategic placement of HARDOX500 wear material in the cutting edge, side cutter and bottom corner to reduce wear2. High strength wear strip configuration, affords the best possible protection to the bottom of the bucket3. All welding is done by skilled worker with, at least, 4 years of excavator attachments' welding experience. Superior Lead Time 1. Most sizes available in 5-7 working days(excluded shipping) Reasonable Price 1. Manufactured in China with lower labor cost and guaranteed quality. 2. We only take a small piece of cake